|

Intelligent

Exhaust and Ventilation Systems |

IMPORTANT

** The CPC-3 Control is being replaced

by the MPC and MPCI Controls in the

Summer

of 2018.**

Literature

|

Tjernlund modulating draft, exhaust and combustion air

systems expand your design options and adapt to changing

conditions for precise control of exhaust and

ventilation processes. |

Benefits

for Architects

|

Building designs not

limited or dictated by needs of

traditional exhaust and ventilation

methods. |

|

Conceal exhaust

terminations and eliminate unsightly

chimneys, vents and louvers. |

|

Eliminate multiple

exhaust vent roof penetrations. |

|

Eliminate large wall

openings for make-up air louvers. |

|

Increase exhaust

termination velocities to avoid issues

with air intakes and windows. |

Benefits for Mechanical Engineers

|

Factory sized and

guaranteed vent, exhaust and combustion

air system performance. |

|

Proven performance on

a wide range of applications throughout

North America. |

|

Route vents with no

practical limitations. |

|

Save money by

eliminating multiple vents and reducing

vent diameter. |

|

Expand existing vent

capacities for equipment upgrades and

additions. |

|

Automatically

modulating performance allows heaters to

operate at optimum efficiencies. |

|

Maintain constant

negative pressure in common exhaust and

dryer vents. |

|

Common vent category

I and III heaters. |

|

|

|

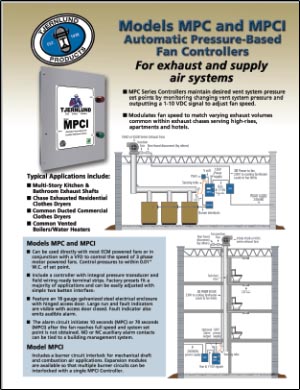

MPC-Series

Demand-Based Exhaust and Supply Fan Speed Controllers |

For modulating draft

and combustion

air systems

|

|

| Problem: Traditional chimneys and

louvers cannot adjust to changes in burner firing rates,

temperatures, winds and building pressures that can

negatively affect burner performance. What’s more, these

fixed systems are often unable to successfully handle

common venting of multiple heaters. |

Solution: MPC-Series controllers maintain desired

system pressure set points by monitoring changing system

pressure and outputting a 1-10 VDC signal to adjust fan

speed. Fan speed is automatically modulated to match

varying exhaust or supply air volume requirements.

Includes controller with integral pressure transducer

and field wiring ready terminal strips.

Factory

presets fit a majority of applications and can be easily

adjusted with two button interface. Activation status

and alarm lights with audible alarm. Auxiliary alarm

contacts. Model MPCI also includes UC1 burner interlock

for mechanical draft and combustion air applications. |

|

|

|

Modulating Draft

Systems for Boilers and Water Heaters |

| Featuring the MPCI

Controller and Auto-Draft®

VSAD-Series Inducers or VSUB-Series

Universal Blowers |

|

| Problem: Erratic draft is the

most common cause of heater performance and operation

problems. Traditional chimneys cannot adjust to varying

winds, temperatures, building pressures and burner

firing rates. A chimney has even a tougher time

providing stable draft when it is serving multiple

heaters. Fan assisted and condensing heaters have

specific draft requirements that are not as forgiving as

atmospheric heaters. |

Solution: Specify the MPCI Controller to

automatically monitor and modulate the speed of either

VSAD-Series Inducers or VSUB-Series Universal Blowers to

maintain optimum draft. MPCI controlled draft

systems feature 100% modulation. Add another MPC-Series

controller to modulate a separate combustion

air blower and/or control a motorized combustion air

louver. Vent heaters hundreds of feet in any direction. |

Auto-Draft® FSAD-Series

Fixed Speed Inducers |

For

single or multiple heaters with draft hood/diverter or

barometric draft control.

Exterior mount fixed speed inducer is suitable for

vertical and side wall venting. Assures a negative

pressure throughout the entire vent system. Features

integral stainless steel handles and hinged housing with

removable hinge pin for ease of installation and

service. Integral tilt switch stops fan operation if

housing is opened. Includes PSA-1 Fan Proving Switch

|

|

|

|

Modulating

Combustion & Make-Up Air Systems |

| Featuring MPC-Series

Controlled Blowers and Fans |

|

Problem:

Conventional combustion and make-up air louvers do not perform

consistently. Simply having a large opening to the

outdoors does not guarantee correct volumes of

combustion air. Depending on wind speeds and direction,

mechanical rooms may get significantly more or less air

than is actually needed. As with chimneys, combustion

air openings must be sized based on the combined firing

rate of all heaters

within the mechanical room. In reality, all heaters

rarely if ever operate at the same time. Uncontrolled

combustion air can cause problems ranging from frozen

pipes to flue gas spillage and flame roll-outs.

Solution: Tjernlund’s modulating combustion &

make-up air

systems always ensure proper air supply,

regardless of the number of heaters operating and

regardless of outdoor conditions. |

|

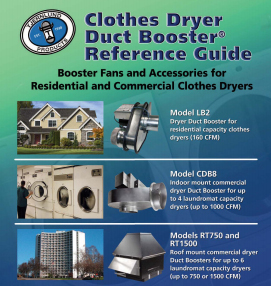

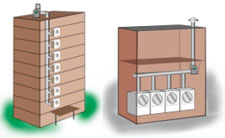

Modulating Dryer

Venting Systems |

| Increases efficiency

and reduces energy by automatically adjusting exhaust

based on the number of dryers in use. |

|

Problem: When commercial clothes dryers are

common vented the exhaust from one dryer fights

another. Residential high rises have the same problem

of properly venting multiple dryers without installing

individual exhaust vents. |

Solution: MPC-Series controlled inducers and blowers

modulate to "perfectly" exhaust common vented

clothes dryers, regardless of the number of dryers

operating. They automatically compensate for

changing pressures, temperatures and winds.

Controlled exhaust results in faster drying laundry.

Overcome Exhaust Vent Design Restrictions

Individual vents can be expensive, if not impossible

to install in multi-story buildings. Laundry room

locations often force exhaust vent lengths to exceed

the dryer manufacturers’ recommendations. MPC-Series

controlled exhaust vents can run hundreds of feet

in any direction and vent diameter can be reduced

by up to 50%. |

|

|

|

|

|

|