Gas Power Venters, GPAK Series, Side Wall Vent Systems

Side Wall Vent Systems save time and money and are excellent for electric to gas/oil, renovations, new construction or for replacing deteriorated chimneys. Sidewall venting saves costly materials and labor on two, three or more story runs. It also increases living space by cutting out interior chases. Proven safety interlocks assure proper exhaust, a feature conventional chimneys do not offer in today’s homes and buildings.

GPAK

Support Documents

Ideal For Replacing Plastic pipe on 80+ gas furnaces

Safety and performance features are time-tested in over a million installations:

- All operating components located indoors for weather protection and easy servicing

- Capacities up to 250,000 BTU/hr

- Accommodates vent pipe runs up to 100 equivalent feet

- Regulated, consistent draft throughout burner cycle

- Built-in Fan Proving Switch interlocks with gas valve

- Kit includes everything needed for installation, except vent pipe. (HS-Series does not come with the vent hood or Draft Control)

- Durable, heavy-duty 5052 aluminum Vent hood. (GPAK Series only)

- AGA design certified for gas furnaces, boilers, pool heaters, unit heaters and commercial water heaters. (HS-Series is ETL approved)

Typical Applications

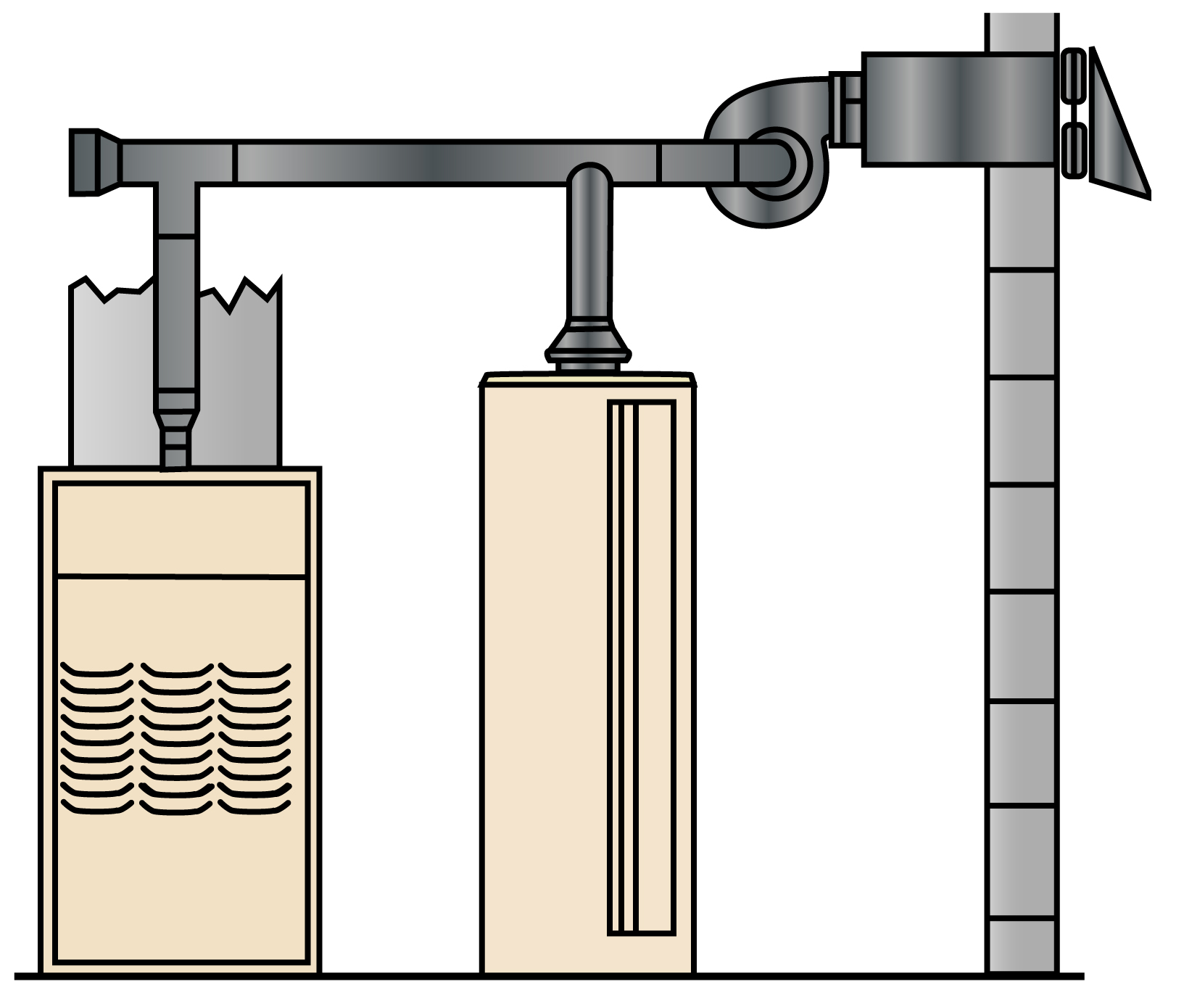

Fan Assisted Furnace & Water Heater

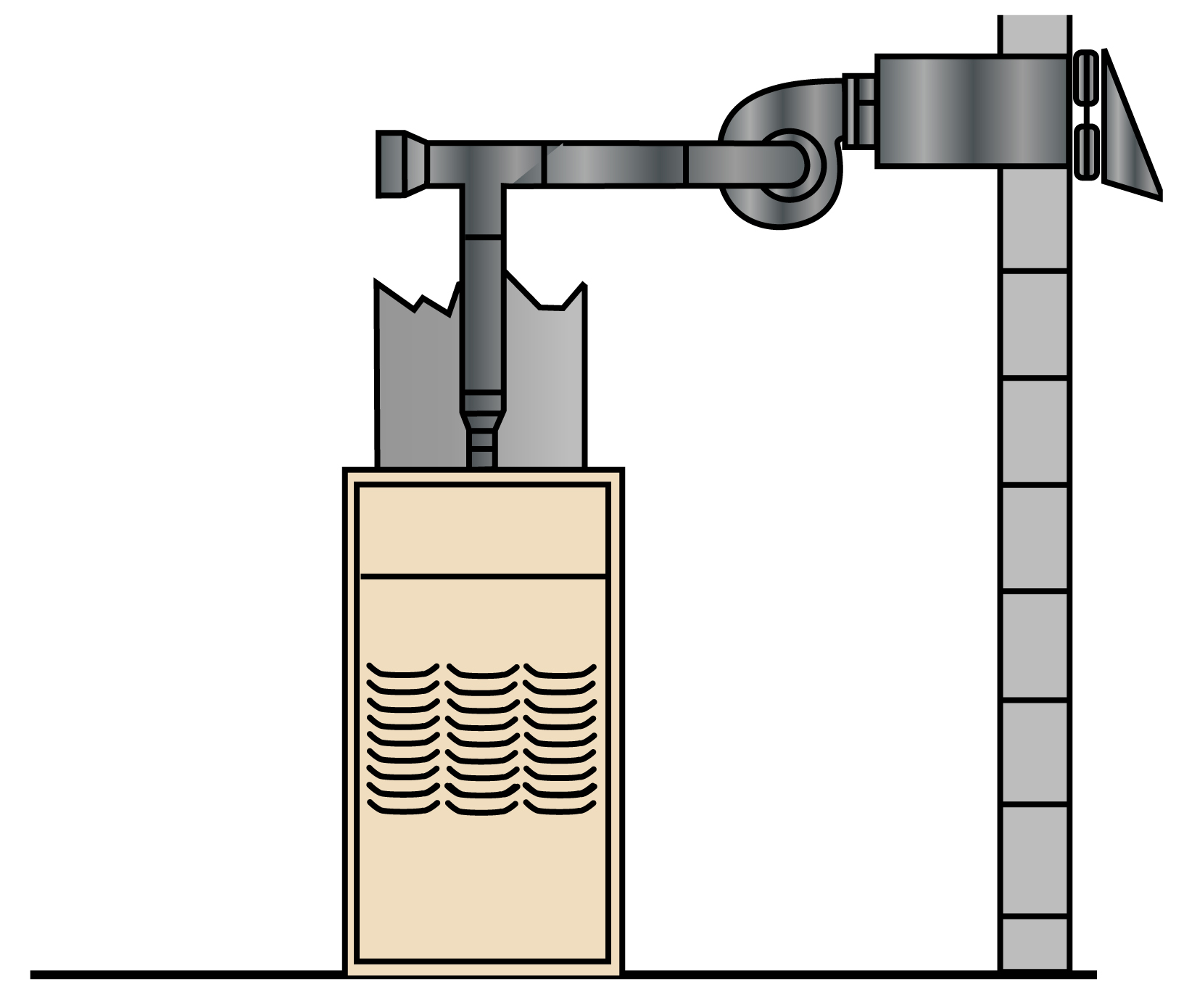

Commercial Water Heaters & Residential Boilers

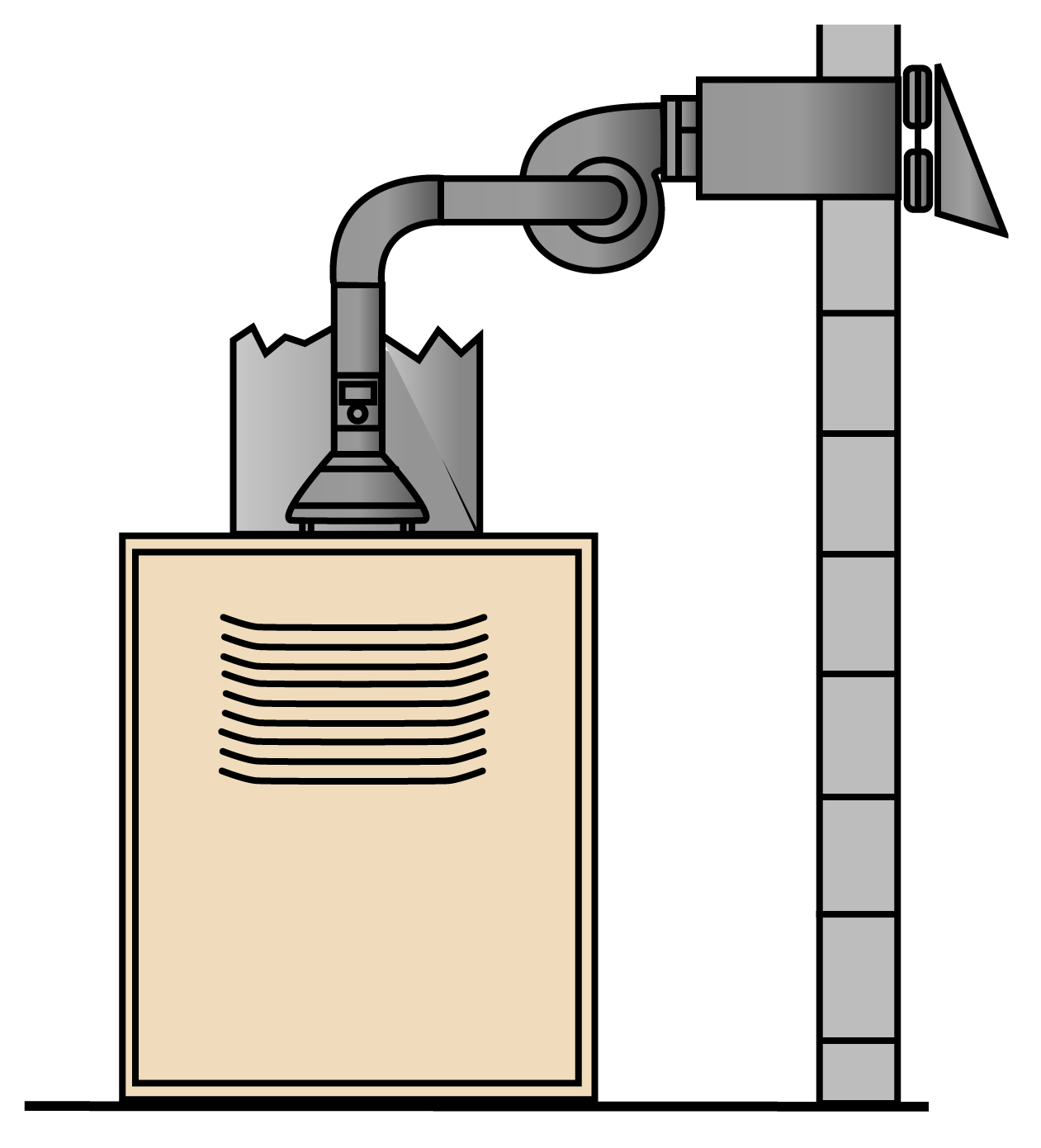

Fan Assisted Furnaces

Gpak-series Model Selection Table

|

Maximum Total Vent Pipe Length (feet)

| ||||

Models | Vent Pipe Diameter | BTU/hr Input | Atmospheric A | Fan Assisted B | *40,000 Atmospheric + Column B C |

GPAKJ | 4” | 45,000 | 100 | 60 | 60 |

75,000 | 100 | 60 | 60 | ||

100,000 | 100 | 60 | N/A | ||

120,000 | 45 | 60 | N/A | ||

GPAK1 | 4” | 100,000 | 100 | 60 | 60 |

120,000 | 100 | 60 | 60 | ||

150,000 | 100 | 60 | 60 | ||

200,000 | 87 | N/A | N/A | ||

250,000 | 40 | N/A | N/A | ||

Notes:

- If the appliance flue outlet is greater than 4″, install a tapered reducer after the draft hood, draft diverter or barometric draft control, reducing vent pipe diameter to 4″. All vent pipe from the appliance to the Power Venter may be 4″.

- Table is based on equivalent length of straight vent pipe. 90 degree elbows are equivalent to 6 feet of straight vent pipe. 45 degree elbows are equivalent to 3 feet of straight vent pipe.

- Determine maximum pipe length from type of equipment being vented and GPAK Model. Column A pipe runs over 30′ linear feet should use Type “B” vent. Column B & C pipe runs over 15 linear feet should use type “B” vent.

- Column C allows for up to a 40,000 BTU/hr input atmospheric water heater common vented with a fan assisted appliance from Column B.

- All reducers and vent pipe are to be supplied by the installer and are available from your local heating wholesaler.

GPAK MOTOR SPECIFICATIONS (Electrical Data) | |

Volts | 115 |

Hertz | 60 |

RPM | 3000 |

Watts | 95 |

Amps | 1.26 |

Thermally Protected | Yes |

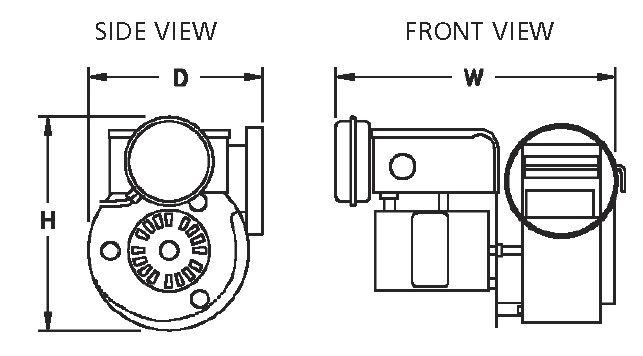

Gpak/hs-series Power Venter Dimensions

| Model | Height (H) | Width (W) | Depth (D) | Inlet/Outlet Diameter |

|

| HSJ GPAKJ | 7 7/8” | 10 ¼” | 7” | 4” | |

| HS1 GPAK1 | 7 7/8” | 11” | 7” | 4” | |

| HS2 | 9 ¼” | 11 ½” | 8 ½” | 6” |

Related Products

Used for Sidewall venting residential/light commercial natural gas, LP or oil fired equipment including: furnaces, boilers, water heaters and unit heaters. All models feature the UC1 Universal Control and a diaphragm Fan Proving Switch safety interlock which will shut down the heating equipment if a venting malfunction occurs.

Used for Sidewall venting commercial natural gas or LP fired equipment including: boilers, water heaters and unit heaters. All models feature the UC1 Universal Control and a diaphragm Fan Proving Switch safety interlock which will shut down heating equipment if a venting malfunction occurs.

Verify that the total BTU/hr input of the heating appliance(s) fall within the proper category listed below.