HS Series, Side Wall Vent Systems

Used for Sidewall venting residential/light commercial natural gas, LP or oil fired equipment including: furnaces, boilers, water heaters and unit heaters. All models feature the UC1 Universal Control and a diaphragm Fan Proving Switch safety interlock which will shut down the heating equipment if a venting malfunction occurs. Built-in adjustable damper also allows regulation for maximum combustion efficiency. UC1 Universal Control features include; adjustable pre and post-purge settings, LED Status/diagnostic indicators, Fan Prover switch monitoring, Interlocks with any 24-120 VAC burner control circuit and also includes “dry” contact actuation option. Easily interlock multiple appliances with our MAC-Series multiple appliance controls.

HSJ, 1, 2

Support Documents

HSUL Series (Discontinued 8/05)

*Replace with HSJ, HS1 or HS2 Models

Designed for atmospheric 24V controlled gas equipment. Includes a 24/115V switching relay and a factory set diaphragm Fan Proving Switch. Built-in adjustable damper also allows regulation for maximum combustion efficiency.

HST Series (Discontinued 7/02)

*Replace with HSJ, HS1 or HS2 Models

Designed for 24V or 115V controlled oil or gas equipment. Includes a dual input 24V or 115V, 1-10 minute post purge Timer/Relay and factory set diaphragm Fan Proving Switch. Built-in adjustable damper also allows regulation for maximum combustion efficiency.

HS115 Series (Discontinued 7/02)

*Replace with HSJ, HS1 or HS2 Models

Designed for 115V controlled gas equipment. Includes a factory set diaphragm Fan Proving Switch. Built-in adjustable damper also allows regulation for maximum combustion efficiency.

HS-Series residential/light commercial model selection table

| MODEL NUMBER | VENT PIPE DIA. | BTU/HR INPUT | MAX. PIPE LENGTH (FEET) AT STACK TEMP. GAS FIRED | MAX. PIPE LENGTH (FEET) AT STACK TEMP. GAS FIRED | MAX. PIPE LENGTH (FEET) AT STACK TEMP. OIL FIRED | CFM AT 70 degrees F. (Static Pressure) 0″ .50″ .75″ 1.0″ 1.4″ |

*HSJ | 4″ | 50,000 75,000 100,000 125,000 | 100′ 100′ 100′ 35′ | 100′ 100′ 100′ 23′ | 100′ 100′ — — | 110 85 67 10 — |

| *HS1 | 4″ 6″ | 150,000 200,000 250,000 300,000 150,000 | 100′ 87′ 40′ 4′ 100′ | 60′ 57′ 12′ — 100′ | 35′ 27′ — — 100′ | 158 115 95 12 — |

*HS2 | 6″ 8″ | 350,000 400,000 450,000 500,000 550,000 600,000 350,000 | 100′ 100′ 100′ 100′ 94′ 15′ 100′ | 100′ 100′ 100′ 72′ — — 100′ | 100′ 100′ 67′ — — — 100′ | 286 235 215 196 158 |

* Oil applications must use the SideShot® Vent Systems or HSJ, HS1, HS2 models including UC1 Universal Control with integral Pre and Post-Purge settings.

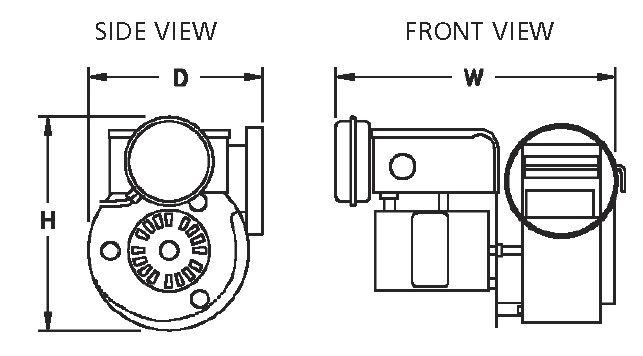

GPAK/HS-Series power venter dimensions

| Model | Height (H) | Width (W) | Depth (D) | Inlet/Outlet Diameter |

|

| HSJ GPAKJ | 7 7/8” | 10 ¼” | 7” | 4” | |

| HS1 GPAK1 | 7 7/8” | 11” | 7” | 4” | |

| HS2 | 9 ¼” | 11 ½” | 8 ½” | 6” |

Related Products

Side Wall Vent Systems save time and money and are excellent for electric to gas/oil, renovations, new construction or for replacing deteriorated chimneys. Sidewall venting saves costly materials and labor on two, three or more story runs.

Used for Sidewall venting commercial natural gas or LP fired equipment including: boilers, water heaters and unit heaters. All models feature the UC1 Universal Control and a diaphragm Fan Proving Switch safety interlock which will shut down heating equipment if a venting malfunction occurs.

Verify that the total BTU/hr input of the heating appliance(s) fall within the proper category listed below.