Rooftop Draft Inducers, In-Line & Rooftop Draft Inducers

Rooftop Draft Inducers

RT-Series Rooftop Draft Inducers for gas, oil, solid fuel and general ventilation applications keep the entire vent system under a negative pressure. The RT-Series are suitable for either metal or tile lined flues and feature removable hinge pins for easy installation & service.

Once installed, the fan assembly can be swung away from the base for direct access to the chimney interior during inspection or cleaning. Speed adjustability fine tunes performance, self-cleaning backward inclined fan blades repel soot build-up and a patented auxiliary cooling system protects the motor from excessive heat. Gas & oil models include a fan proving switch and can be paired with Tjernlund’s interlock controls for automatic and safe operation.

Can be used as a chimney fan in solid fuel fireplaces. Hearth versions include a speed control with the chimney fan.

The Alternative to In-Line Inducers

- The solution for inaccessible and short length vent connectors & chimneys

- Great for noise sensitive installations

- Connects easily to single wall, insulated or tile lined flues

- Rooftop mounting maintains negative pressure throughout the entire vent system

Clamshell design means faster, easier installation and maximum accessibility to chimney or vent pipe during inspection and servicing.

Rooftop Inducer

Support Documents

Features

- Stainless steel backward inclined impeller repels soot and lint

- Clamshell design for easy installation, inspection and service

- Patented motor cooling system automatically activates, extending motor life

- PSC ball bearing motors with -40˚F low temp lubricant

- Hi-temp powder coat finish

Maximize Performance & Efficiency

A common chase, duct or vent does not efficiently exhaust multiple sources that operate independently. Clothes dryers, boilers and water heaters all depend on a consistent, moderate exhaust to operate properly. When they share a common exhaust duct or vent, their performance and efficiency is compromised by wide swings in exhaust/draft pressure as equipment cycles and in some cases modulates.

Rooftop Inducer

Support Documents

COP2 Constant Operating Pressure Control

- Modulates fan speed to match changing exhaust or draft requirements

- Incorporates a 120/1/60 Variable Frequency Drive and Pressure Transducer to monitor flue draft and modulates fan speed to maintain user adjustable negative pressure set point

NOTE: When used to exhaust gas or oil fired heating equipment, a CIC1 Burner Interlock Control must be installed. Easily interlock multiple appliances with the CIC1 and our MAC-Series multiple appliance controls.

Rooftop Draft Inducer Selection Tables

Atmospheric Gas or Oil Fired with Draft Hood (at Sea Level) | |||

Model | Vent Pipe Diameter | Btu/hr Input | Max. Equivalent Pipe Length (Ft) @ 400˚F |

RT750 | 8” | 400,000 to 700,000 | 100’ |

RT750 | 8” | 700,000 to 900,000 | 50’ |

RT750 | 8” | 900,000 to 1,100,000 | 25’ |

RT750 | 10” | 700,000 to 1,000,000 | 100’ |

RT750 | 10” | 1,000,000 to 1,200,000 | 50’ |

RT750 | 10” | 1,200,000 to 1,300,000 | 25’ |

RT1500 | 12” | 1,000,000 to 2,000,000 | 100’ |

RT1500 | 12” | 2,000,000 to 2,400,000 | 50’ |

RT1500 | 12” | 2,400,000 to 2,600,000 | 25’ |

RT1500 | 14” | 2,000,000 to 2,500,000 | 100’ |

RT1500 | 14” | 2,500,000 to 2,700,000 | 50’ |

RT1500 | 14” | 2,700,000 to 2,900,000 | 25’ |

Fan Assisted/Power Burner Gas or Oil Fired with Barometric Draft Control (at Sea Level) | |||

Model | Vent Pipe Diameter | Btu/hr Input | Max. Equivalent Pipe Length (Ft) @ 400˚F |

RT750 | 8” | 500,000 to 900,000 | 100’ |

RT750 | 8” | 900,000 to 1,200,000 | 50’ |

RT750 | 8” | 1,200,000 to 1,400,000 | 25’ |

RT750 | 10” | 900,000 to 1,200,000 | 100’ |

RT750 | 10” | 1,200,000 to 1,500,000 | 50’ |

RT750 | 10” | 1,500,000 to 1,700,000 | 25’ |

RT1500 | 12” | 1,200,000 to 2,700,000 | 100’ |

RT1500 | 12” | 2,700,000 to 3,200,000 | 50’ |

RT1500 | 12” | 3,200,000 to 3,500,000 | 25’ |

RT1500 | 14” | 2,700,000 to 3,500,000 | 100’ |

RT1500 | 14” | 3,500,000 to 3,700,000 | 50’ |

RT1500 | 14” | 3,700,000 to 3,900,000 | 25’ |

- Due to their extended speed reduction capabilities, COP2 controlled inducers minimum burner inputs are reduced to 100,000 Btu/hr for all draft applications.

- Select inducer based on Btu/hr input of appliance(s) rather than diameter of appliance vent outlet or chimney.

- To determine equivalent feet, add the total length of straight vent pipe plus 10 ft. for each 90˚ elbow and 5 ft. for each 45˚ elbow.

Fireplaces and Ovens | |

Model | Maximum Open Face Area* |

RT750H | 14 Square Feet |

RT1500H | 28 Square Feet |

- Determine vertical and horizontal face opening of hearth in square feet (if open on sides or back, total all openings)

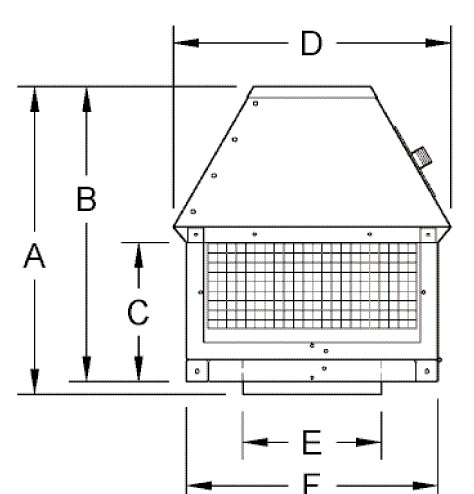

Dimensions and Specs

| Model | RT750(H) | RT1500(H) |

| A | 17 1/2″ | 22 1/2″ |

| B | 16 3/4″ | 21 3/4″ |

| C | 8” | 11 1/4″ |

| D | 16” | 18 1/2″ |

| E (inlet) | 7 15/16” | 11 15/16” |

| F | 14 1/2″ | 17” |

Model | RT750(H) | RT1500(H) |

Voltage | 120 VAC | 120 VAC |

HP | 1/12 | 1/2 |

Amps | 1.2 | 5.8 |

Weight | 34 lbs | 47 lbs |

Related Products

Tjernlund In-Line Draft Inducers assure positive draft when restricted boilers and furnaces, poor chimneys or negative pressures in buildings prevent proper exhaust of combustion gases.