|

RESIDENTIAL / LIGHT COMMERCIAL

COMBUSTION AIR IN-FORCER™ |

THE

PROBLEM:

Incomplete

combustion or poor draft due to inadequate combustion air in too-tightly

constructed buildings can result in carbon monoxide creation, poor equipment

efficiency, reduced equipment life and nuisance service calls.

|

|

THE

SOLUTION:

The

IN-FORCER mechanically draws outside air indoors on demand to provide fresh

air for safe and efficient operation of fuel burning equipment. |

The Combustion Air IN-FORCERTM

offers all these advantages:

|

Affordably priced and installs

fast with simple electrical interlock. |

|

Reduces cold air drafts through windows, doors,

fireplaces caused

by excessive negative pressure. |

|

Automatic regulated control of

incoming fresh, combustion air. |

|

Light indicates

IN-FORCER is operating properly. |

|

Uses indoor air to temper outdoor

air for increased comfort. |

|

Interlock shuts down

burner if intake elbow is blocked or performance

is significantly reduced. |

|

Damper closes during off cycles to prohibit cold

air entry and warm air

loss. |

|

Helps replace air

vented by exhaust fans, fireplaces, etc. |

|

Reduces negative pressure, a major cause of flue

gas spillage and radon

gas entry. |

|

|

Steps

to Selecting the Right Combustion Air IN-FORCERTM

MODEL PAI-2G

MODEL PAI-2O

(For 24 VAC Control Circuits) (For 115 VAC Control Circuits)

|

Step 1) |

Determine the required CFM from Table A

based on equipment type and BTU/hr. input of the heater(s).

|

| Step 2) |

Calculate

the equivalent length of the 3" PVC inlet pipe and the

6"outlet duct (if used) from Table

B.

|

| Step 3) |

Referencing Table

C and your calculated equivalent length, verify that the CFM performance

listed in Table C is equal to or greater than that

determined in Table A. Select Model PAI-2G or PAI-2O

Series

based on control circuit voltage.

|

REQUIRED CFM BASED ON EQUIPMENT TYPE

AND BTU/HR INPUT (TABLE A)

|

BTU/HR INPUT

|

GAS ATMOSPHERIC

|

GAS INDUCED

COMBUSTION

|

OIL FLAME RETENTION

|

|

40,000

|

21

|

11

|

12

|

|

50,000

|

26

|

14

|

15

|

|

60,000

|

32

|

17

|

18

|

|

70,000

|

37

|

19

|

21

|

|

80,000

|

42

|

22

|

24

|

|

90,000

|

47

|

25

|

27

|

|

100,000

|

53

|

28

|

30

|

|

110,000

|

58

|

30

|

33

|

|

120,000

|

63

|

33

|

37

|

|

130,000

|

68

|

36

|

40

|

|

140,000

|

74

|

39

|

43

|

|

150,000

|

79

|

41

|

46

|

|

160,000

|

--

|

44

|

49

|

|

|

BTU/HR INPUT

|

GAS ATMOSPHERIC

|

GAS INDUCED

COMBUSTION

|

OIL FLAME RETENTION

|

|

170,000

|

--

|

47

|

52

|

|

180,000

|

--

|

50

|

55

|

|

190,000

|

--

|

52

|

58

|

|

200,000

|

--

|

55

|

61

|

|

210,000

|

--

|

58

|

64

|

|

220,000

|

--

|

61

|

67

|

|

230,000

|

--

|

63

|

70

|

|

240,000

|

--

|

66

|

73

|

|

250,000

|

--

|

69

|

76

|

|

260,000

|

--

|

72

|

79

|

|

270,000

|

--

|

74

|

--

|

|

280,000

|

--

|

77

|

--

|

|

290,000

|

--

|

80

|

--

|

|

|

|

CALCULATING EQUIVALENT

LENGTH (TABLE B)

The performance shown is

based on equivalent feet. To determine

the

equivalent feet of an installation add the length of the 3" PVC inlet pipe

plus the equivalent length of any elbows. Do not include the intake elbow

or gooseneck equivalent loss, they have already been factored into the

performance data. Use the same method to determine the equivalent feet

if a 6" outlet duct is installed.

EQUIVALENT LENGTH OF ELBOWS

|

ELBOW DIAMETER

|

90 degree elbow

|

45 degree elbow

|

|

3" PVC

|

5'

|

2.5'

|

|

6"

|

10'

|

5'

|

IN-FORCERTM

PERFORMANCE DATA (TABLE C)

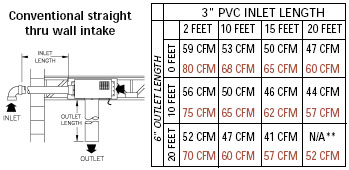

| Conventional straight thru wall intake

Models PAI-1G & PAI-1O

(Discontinued)

Models PAI-2G & PAI-2O

** Below Fan Prover Set Point |

|

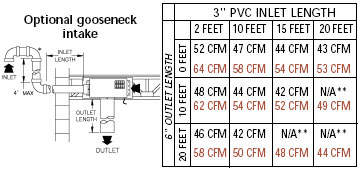

| Optional gooseneck intake

Models PAI-1G & PAI-1O

(Discontinued)

Models PAI-2G & PAI-2O

** Below Fan Prover Set Point

|

|

DIMENSIONS & MOTOR SPECIFICATIONS

|

A

|

B

|

C

|

D

|

E

|

F

|

|

|

17 3/4"

|

15 5/8"

|

8 7/8"

|

2 5/8"

|

8"

|

9 3/8"

|

MOTOR SPECIFICATIONS

115/1/60 1600 RPM

80 WATTS 1.0 FLA

|